Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

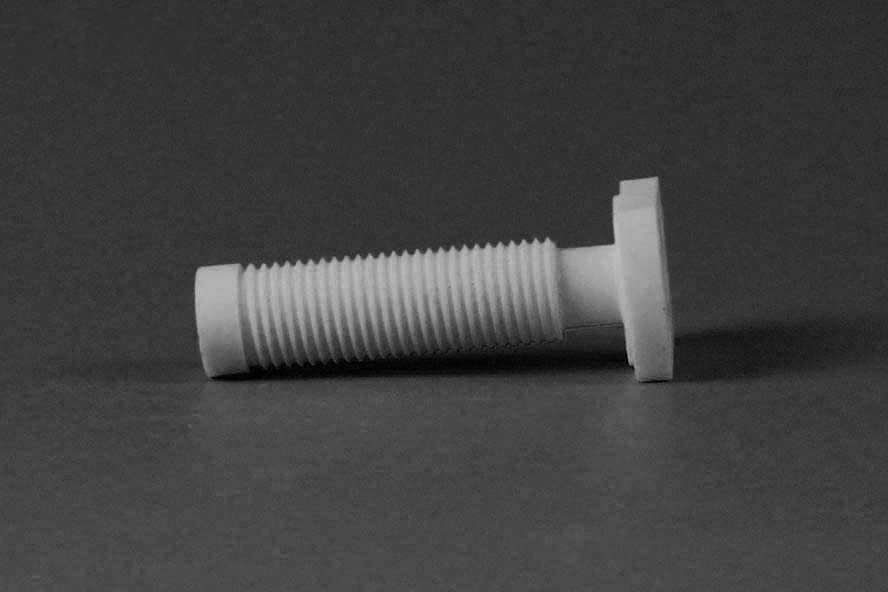

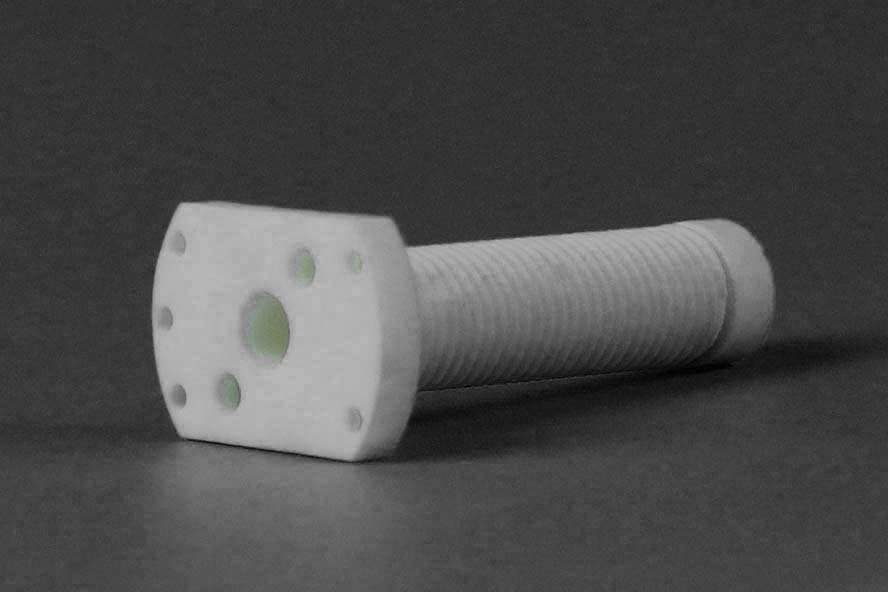

Alumina ceramic screws

Email:beikenano@gmail.com

Email:beikenano@gmail.com

Alumina ceramic screw Ceramic screw is made of zirconia, alumina and other materials. It has relatively stable physical and chemical stability. The physical stability is mainly manifested in high and low temperature resistance, insulation, anti-magnetic, and abrasion resistance; chemical stability The main surface is corrosion resistance and oxidation resistance. The flexural strength of Al2O3 porcelain sintered products can reach 250MPa, and the hot-pressed products can reach 500MPa. The Mohs hardness of Al2O3 ceramics can reach 9, coupled with excellent wear resistance, so it is widely used in the manufacture of cutting tools, ball valves, grinding wheels, ceramic nails, bearings, etc.

Alumina ceramics can be made into various cutting tools for industrial processing. The most common ones are the following:

Pure Al2O3 ceramic tool

The optimal cutting speed of Al2O3 ceramic tools is higher than that of ordinary cemented carbide tools, which can greatly improve the cutting efficiency of different materials. With a lot of research by scientists, other components are added to form two phases or exist in the form of solid solution in Al2O3-based composite ceramics and whisker-reinforced ceramics. These technologies make up for the shortcomings of pure Al2O3 ceramics, thereby improving its cutting performance and durability.

Composite Al2O3 ceramic tool

Al2O3-carbide ceramic cutting tools are made by adding a certain amount of carbide to Al2O3 to improve its strength, wear resistance, impact resistance and high temperature performance. Due to the addition of metal, the connection strength between Al2O3 and carbide is improved, and the performance is improved. This type of ceramic tool is suitable for processing hardened steel, alloy steel, manganese steel, chilled cast iron, nickel-based and cobalt-based alloys, and non-metallic materials Wait.

Toughened Al2O3 ceramic tool

Toughening Al2O3 ceramic tools refers to adding toughening or reinforcing materials to the Al2O3 matrix. Currently commonly used toughening methods include: ZrO2 phase transformation toughening, whisker toughening, and second phase particle dispersion toughening.

Warm tips: Kaifa products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately.

Quality AssuranceHigh standards of the industry-leading

|

Ceramic tube Thermocouple protection tube |

|

Ceramic rod Ceramic shaft sleeve insulated |

|

Ceramic crucible High quality and high temperature resistant |

|

T-shaped concave convex tube High temperature insulator porcelain mouth porcelain |

|

Ceramic plate Alumina plate, ceramic plate, bearing plate, |

|

Ceramic gasket High temperature resistant ceramic ring, |

|

Screw nut Insulating screws, corrosion-resistant bolts, |

|

Ceramic ball Alumina and zirconia ultrafine grinding media. |