Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

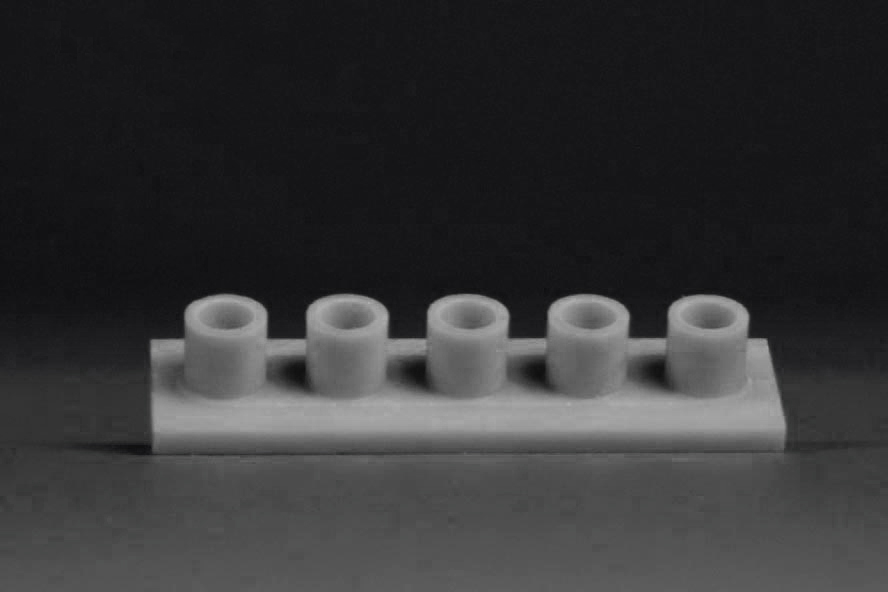

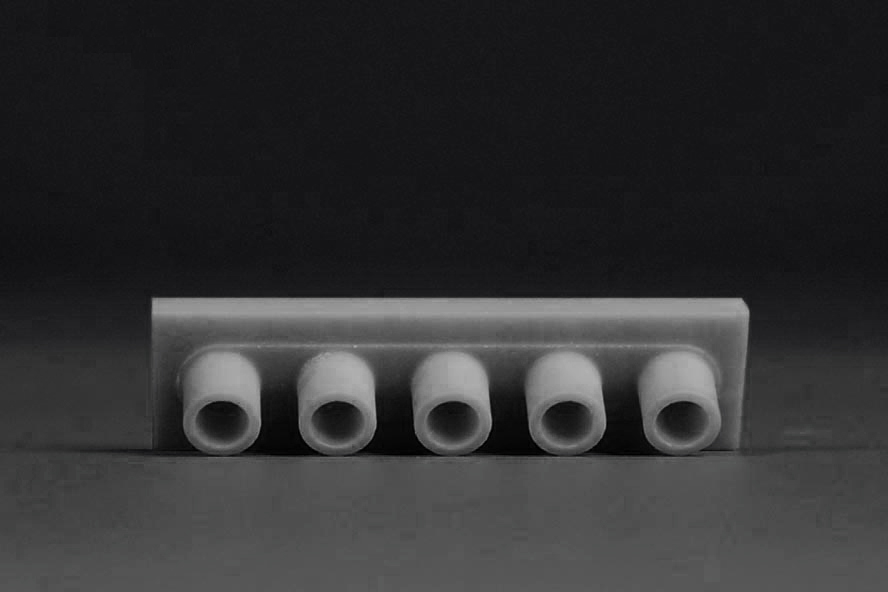

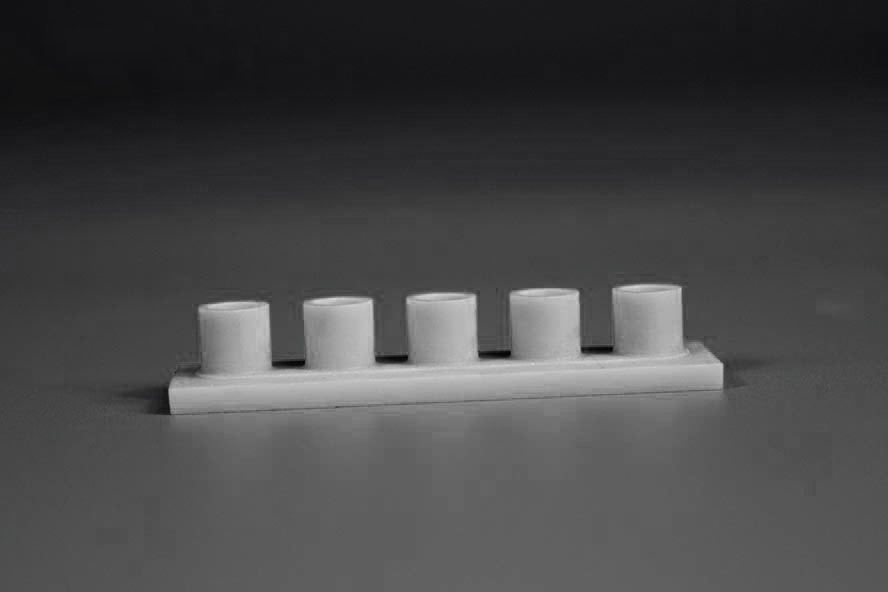

Aluminum nitride ceramic parts

Email:beikenano@gmail.com

Email:beikenano@gmail.com

Aluminum nitride ceramics have excellent properties such as high thermal conductivity, high strength, high resistivity, low density, low dielectric constant, non-toxicity, and thermal expansion coefficient matching Si, and will gradually replace traditional high-power LED substrate materials. The most promising ceramic substrate material in the future. Generally speaking, the luminous efficiency and service life of the LED will decrease with the increase of the junction temperature. When the junction temperature reaches 125°C or higher, the LED may even fail. In order to keep the LED junction temperature at a lower temperature, a heat dissipation substrate material with high thermal conductivity and low thermal resistance and a reasonable packaging process must be used to reduce the overall package thermal resistance of the LED.

Aluminum nitride ceramics have excellent comprehensive properties, with a theoretical thermal conductivity of 320W/(m), excellent thermal conductivity, reliable electrical insulation, low dielectric constant and loss, non-toxic and thermal expansion coefficient matching silicon. Utilizing the heat resistance and melt erosion resistance and thermal shock resistance of AIN ceramics, GaAs crystal crucibles, Al evaporating dishes, magnetic fluid power generation devices and high-temperature turbine corrosion-resistant parts can be made, and its optical properties can be used as infrared windows. Aluminum nitride film can be made into high-frequency piezoelectric components, super-large-scale integrated circuit substrates, etc. Aluminum nitride is heat-resistant, resistant to corrosion by molten metal, stable to acid, but easily corroded in alkaline solutions. The new surface of AIN will react when exposed to humid air to form a very thin oxide film. Using this feature, it can be used as a crucible and casting mold material for melting aluminum, copper, silver, lead and other metals. AIN ceramics have good metallization properties and can replace toxic beryllium oxide ceramics and are widely used in the electronics industry.

Warm tips: Kaifa products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately.

Quality AssuranceHigh standards of the industry-leading

|

Ceramic tube Thermocouple protection tube |

|

Ceramic rod Ceramic shaft sleeve insulated |

|

Ceramic crucible High quality and high temperature resistant |

|

T-shaped concave convex tube High temperature insulator porcelain mouth porcelain |

|

Ceramic plate Alumina plate, ceramic plate, bearing plate, |

|

Ceramic gasket High temperature resistant ceramic ring, |

|

Screw nut Insulating screws, corrosion-resistant bolts, |

|

Ceramic ball Alumina and zirconia ultrafine grinding media. |