Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

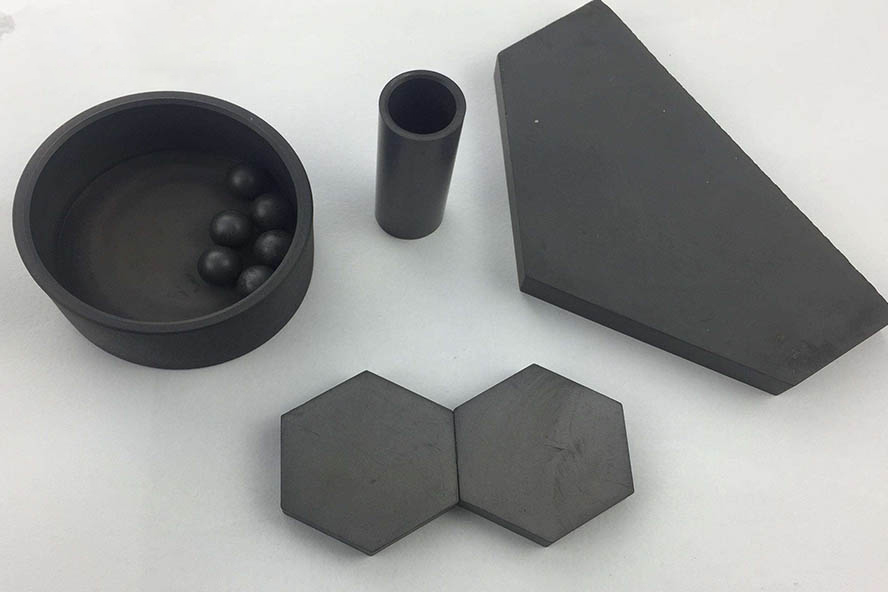

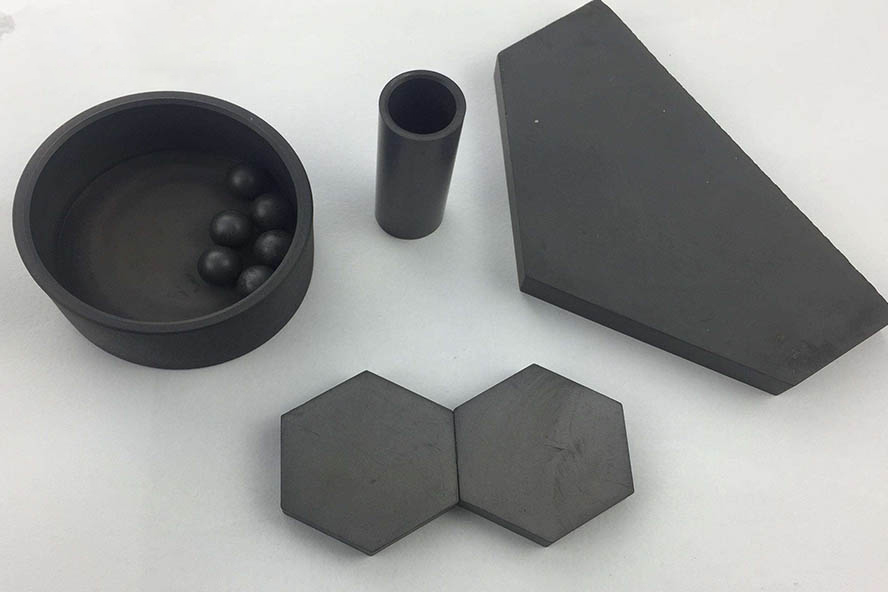

Boron carbide ceramics

Email:beikenano@gmail.com

Email:beikenano@gmail.com

Introduction to Boron Carbide Ceramics

Main features of boron carbide ceramics:

Boron carbide ceramics is still a relatively small ceramic product at present. It has the characteristics of small particle size distribution, uniform particles, high purity, and better microscopic morphology. In addition to these, it has high hardness and very good chemical stability, so it is also used as a wear-resistant additive for materials. It is called the "Three Musketeers of Superhard Materials" together with cubic boron nitride and diamond, and the measured Mohs hardness reaches 9.3. At the same time, boron carbide ceramic also has very excellent thermal conductivity and is a good semiconductor material. It also has a good antioxidant effect even at high temperatures.

Application fields of boron carbide ceramics:

1. Boron carbide is an efficient thermal neutron absorber, so it is widely used as a control material and shielding material in nuclear reactors. Applying its ceramic coating to the nuclear industry has achieved quite good results.

2. Application of boron carbide in materials Boron carbide has broad applications in materials: boron carbide is used as an abrasive for grinding and polishing of engineering ceramics, gemstones, cemented carbide, etc.; boron carbide has high hardness and can be used to make sandblasting nozzles And nozzles for high-pressure water jet cutting; boron carbide has good corrosion resistance and stable chemical properties. It can be used to make the tip of a flow transmitter for rocket liquid engine fuel or as a corrosion-resistant and friction-resistant device in ceramic gas turbines; carbonization Boron has good stability and thermal conductivity to molten iron, and can be used as a continuous casting mold in the machinery industry. In addition, the application of boron carbide in coating materials: boron carbide has high hardness, wear resistance, radiation resistance, chemical stability, and can be used to make amorphous boron carbide coated tools.

3. Using the thermoelectric properties of boron carbide, boron carbide/graphite thermocouples can be made.

4. Boron carbide powder can be used as a boronizing agent for steel or other alloys after being activated by halogen. Boronized on the steel surface to form a thin layer of iron boride to enhance the strength and wear resistance of the material; high hardness and high grinding ability , Added to the metal-based friction material, greatly improving the friction coefficient value of the material.

5. Excessive hardness of synthetic diamond (Mohs hardness 10) will scratch the surface when grinding the sapphire wafer, which will affect the light transmittance of the wafer and is expensive. Insufficient silica hardness (Mohs hardness 7) and poor grinding force are time-consuming and labor-intensive in the grinding process. Boron carbide abrasive (Mohs hardness 9.3) has become the most ideal material for processing and grinding sapphire crystals. Boron carbide abrasives have excellent performance in double-sided grinding of sapphire wafers and back thinning and polishing of sapphire-based LED epitaxial wafers

6. Boron carbide has an anti-oxidation effect in carbon-containing refractories, which can densify the product and prevent the oxidation of carbon in carbon-containing refractories. At the same time, it will react at 1000°C~1250°C to generate (9AL2O3•2B2O3) columnar crystals distributed in the refractory. In the matrix and gaps, the porosity is reduced, the medium temperature strength is improved, and the volume of the generated crystals expands, which can heal volume shrinkage and reduce cracks.

Warm tips: Kaifa products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately.

Quality AssuranceHigh standards of the industry-leading

|

Ceramic tube Thermocouple protection tube |

|

Ceramic rod Ceramic shaft sleeve insulated |

|

Ceramic crucible High quality and high temperature resistant |

|

T-shaped concave convex tube High temperature insulator porcelain mouth porcelain |

|

Ceramic plate Alumina plate, ceramic plate, bearing plate, |

|

Ceramic gasket High temperature resistant ceramic ring, |

|

Screw nut Insulating screws, corrosion-resistant bolts, |

|

Ceramic ball Alumina and zirconia ultrafine grinding media. |