Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

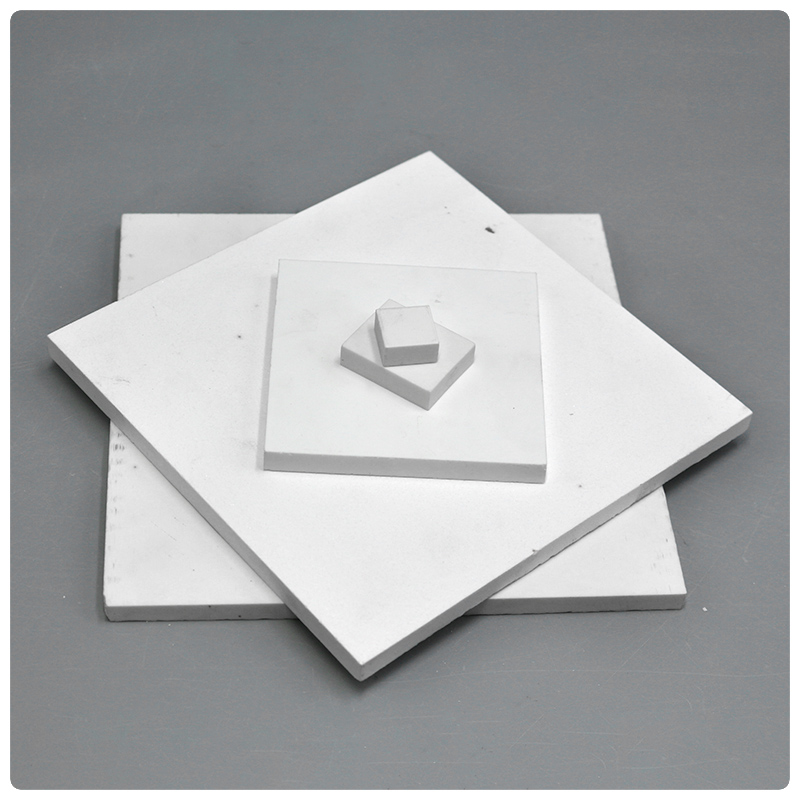

Tin oxide ceramic plate

Ceramic material: tin oxide

Machining accuracy: ±0.001mm

Product features: wear resistance, high temperature resistance, corrosion resistance

Available Colors: Off-White

Customized processing: can be customized according to drawings and samples

Email:beikenano@gmail.com

Email:beikenano@gmail.com

Tin dioxide ceramic is an n-type semiconductor and an excellent transparent conductive material. It has broad application prospects in the fields of gas sensors, liquid crystal displays, photodetectors, solar cells, photocatalysis, electrocatalysis, and protective coatings. , is also the first commercial transparent conductive material. In order to improve its conductivity and stability in industry, it is often used by doping. For example, doping with elements such as Sb, V and Ni can greatly increase the conductivity. The ceramic material based on tin dioxide not only has good electrical conductivity and high density, but also has high temperature resistance, high temperature load softening point and excellent corrosion resistance, so it can be used as electrode material for high temperature heating such as crucible, thermocouple protection Covers and linings of chemical equipment, etc.

Properties of SnO2 Ceramics

The thermal expansion coefficient of SnO2 ceramics is small (1/2 of that of alumina ceramics), the thermal conductivity is high, and the thermal stability is higher than that of alumina ceramics and zirconia ceramics.

The volatilization rate of SnO2 ceramics is low at 1400 °C, and the volatilization is strong above 1500 °C. Therefore, SnO2 ceramics can only be used in an oxygen atmosphere below 1500 °C.

The specific resistance of pure SnO2 ceramics at room temperature is 1010~1011Ω·cm. However, adding divalent or trivalent metal oxides will reduce its specific resistance.

For example, after adding Sb2O3 and CuO, the specific resistance of SnO2 is reduced by 7 to 8 orders of magnitude.

SnO2 ceramics have strong resistance to the erosion of glass liquid. At 1200 ℃, the corrosion resistance of SnO2 ceramic electrode to calcium glass is 1~2 times higher than that of fused corundum.

At 1500 ℃, the alkali corrosion resistance is 4 times higher than that of fused corundum. It is also resistant to corrosion by lead glass, arsenic glass, iron glass, copper glass.

Warm tips: Kaifa products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately.

Quality AssuranceHigh standards of the industry-leading

|

Ceramic tube Thermocouple protection tube |

|

Ceramic rod Ceramic shaft sleeve insulated |

|

Ceramic crucible High quality and high temperature resistant |

|

T-shaped concave convex tube High temperature insulator porcelain mouth porcelain |

|

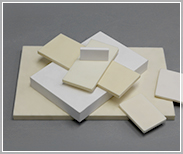

Ceramic plate Alumina plate, ceramic plate, bearing plate, |

|

Ceramic gasket High temperature resistant ceramic ring, |

|

Screw nut Insulating screws, corrosion-resistant bolts, |

|

Ceramic ball Alumina and zirconia ultrafine grinding media. |